Adhesive labels, their production and variety

Many people think that production of adhesive labels is a very simple solution. However, a closer look at their production process reveals that it’s not really like that. Label production is a product design process that distinguishes your product from others placed on the same shelf.

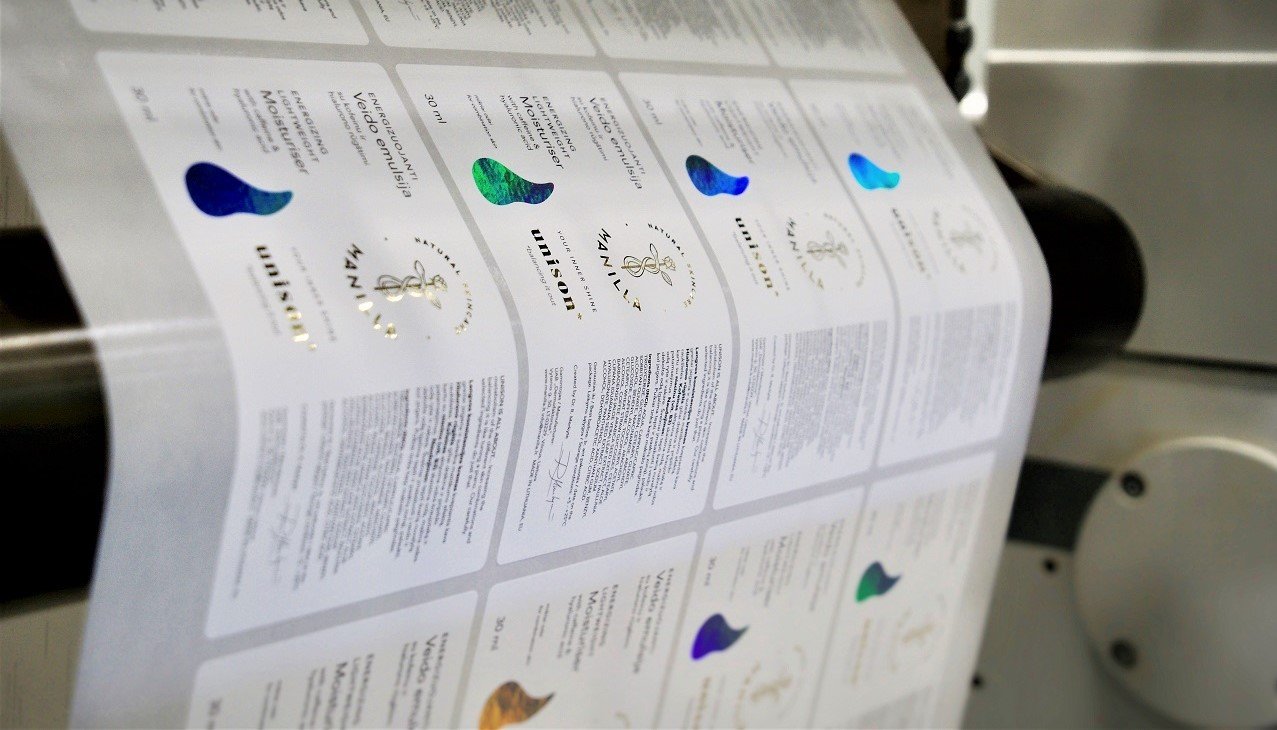

In the production of adhesive labels, various printing technologies are used, unique printing elements are created. With them, the appearance of the product can influence the consumer’s decision to buy/not buy the product.

PakMarkas uses flexographic, silk screening and digital printing technologies for the production of adhesive labels. Labels can be produced by optionally using additional parameters.

- Varnishing. Full or partial varnishing of adhesive labels helps to visually highlight the desired

elements. Varnishing can be matte or glossy. Varnishing is felt even when touching the product, which creates an impression of aesthetics and luxury.

elements. Varnishing can be matte or glossy. Varnishing is felt even when touching the product, which creates an impression of aesthetics and luxury. - Primarily, it increases the protection of the label against external factors. Furthermore, when laminating with glossy or matte laminate, it is also possible to visually create absolutely non-standard solutions. The laminate can serve as an element of the label design.

- Hot foiling. Using a press, graphic or textual elements of print are covered with metallized foil. The foil can be of different colours. This printing element adds luxury and exclusivity to adhesive labels.

- Silk screening. A generous layer of paint varnish is transferred with the printing form. Using screen printing, the design elements of the label become prominent, well felt when touching the product. This technology is also used for Braille.

- Debossing or embossing is a design element that diversifies the look of the label. Debossed or embossed labels are often associated with luxury and quality products.

- Perforation is the formation of a tear line. A row of holes is formed on the edges of the label or in other places. The purpose of the perforation is to make it easy to tear off the designated portion of the label without damaging the entire label.

VARIETY OF ADHESIVE LABELS

We produce a really wide variety of adhesive labels. We use various technologies and raw materials for their production. We can offer the following adhesive label products:

- DPG labels are deposit container labels that are popular throughout Europe. Our company is one of the few companies in the European Union authorized to print labels with the DPG deposit mark for the

German beverage market.

German beverage market. - Double-layer labels are labels that consist of two layers. They are often used when you want to provide more information about a product or information in several languages. Multiple adhesion allow the user to repeatedly return to relevant product information.

- Wash-off labels are labels that are usually used on glass containers and are easy to wash off at a certain temperature.

- Label blanks are products that are often used in trade as barcodes and the desired text can be printed on them with special printers.

- Water-soluble labels are a product that completely dissolves in water and is also environmentally friendly. They are used for medical and laboratory equipment, food containers or even in the logistics industry.

- Antibacterial labels are labels for the production of which antibacterial varnish is used. The use of these labels stops spreading of viruses and bacteria.

- Coloured labels are the labels we are used to seeing in stores. They are mostly glued on the packaging of food products, hygiene and chemical products. Silk-screening, cold and hot foiling, lamination, varnishing, embossing or debossing, and printing on glue can be used for their decoration.

- Label stickers Label stickers are digitally printed labels that are affixed to food and beverage packages. These printing properties allow producing small and medium runs of labels faster, to provide different (variable) information on the label, such as number, barcode. We use paints that can directly come into contact with food.

By using the above adhesive label properties, you can provide consumers with more information, drive them to action, tell the story of your product, and thus increase your brand awareness.