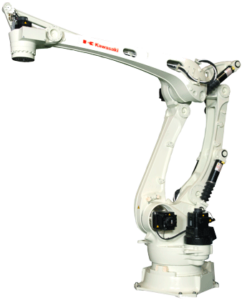

Industrial palletizing robots

Palletizing opportunities at today’s speed

Kawasaki palletizing robots make it possible to carry out the picking and placing tasks very quickly. The RD080N robot arm completes 900 cycles per hour (400 mm up and down movements and 2000 mm left and right movements) with a load of 80 kg, while the CP180L robot achieves the best performance in this market segment – 2050 cycles per hour with a load of 130 kg.

Compact design

The Kawasaki RD080N robot arm is designed for situations where a compact high-speed palletizing solution is required. Despite its sleek, space-saving design, the RD080N can work with loads of up to 80 kg and can stack products to a height of over 2 metres.

Space and energy saving controller

The CP-series E03 controller is only 25% the size of a standard palletizing controller (or 41% the size of a transformer). It can be fitted under conveyors or other equipment. The E03 controller’s energy recuperation system generates power during the robots stopping process and thus reduces both the power consumption costs and CO2 emissions.

For more: KAWASAKI_PALLETIZING-SERIES

If you would like to purchase this device, contact us by phone +370 5 205 2900 or e-mail us at info@pakmarkas.lt.