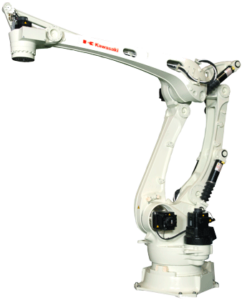

Industrial painting robots

K-series painting robots combine high operational efficiency with easy system integration. Kawasaki offers five models suitable for any robot painting program: from a single robot cell to integrated systems of several robots.

Hollow back axes

Internal hoses can be embedded in the arms of the K-series robots, which solves the issue of excessive paint spray over hoses and thus reduces the risk of contaminating painted surfaces.

Simple integration

Kawasaki also offers a controller that facilitates system development and links with peripheral equipment, e.g. robot transporter, blank lifting device, rotation device, etc. The controller is a user-friendly graphical interface that allows users to centrally control the components of the robotic system.

Programming flexibility

The K-series robots can be programmed in two ways: by using the controller or a computer, or by using one of the two programming techniques – Block Step or the AS language. The Block Step programming method removes the need for training the program, which is time consuming, through the use of automatic path-creating software. The powerful AS language enables maximum flexibility and allows the user to develop improved logic, manipulate certain parts of the program, integrate peripheral components and control the application process.

For more: KAWASAKI_K-SERIES

If you would like to purchase this device, contact us by phone +370 5 205 2900 or e-mail us at info@pakmarkas.lt.